Process flow of scrap tire pellet production line

With the continuous development of society and the improvement of people’s living standards, cars have become a must-have hardware for families, bringing convenience to travel and improving the quality of life and economy. The increasing number of cars is directly proportional to the amount of scrapped tires. At this time, the existing social problems are very obvious. The black polluted waste tires will only increase the pressure on the social environment. The rubber tire processing line boutique-waste tire recycling and processing granule production line was born to keep pace with the times, and has achieved the wealth dreams of many investors. More perfect, the social environment pressure is greatly reduced.

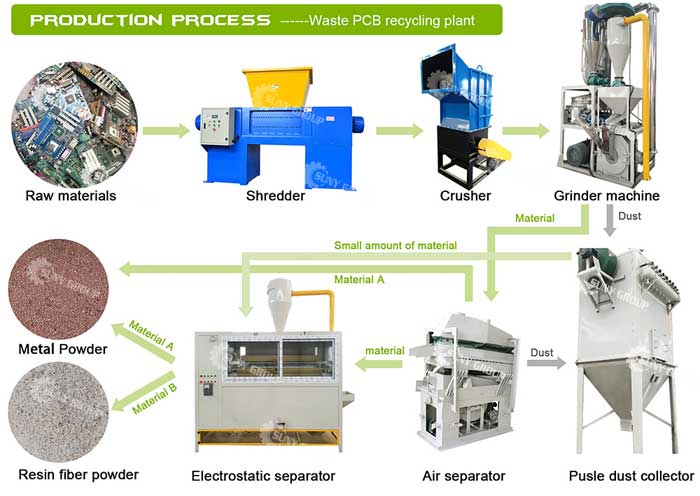

Process flow of waste tire recycling and processing pellet production line:

Starting from the separation of the rim steel wire, the rim steel wire is processed by a tire cutting machine and a wire extruder to obtain the first economically valuable product, and the remaining tires go through a shredder (you can also choose a small tire to disassemble a three-piece set) ) into blocks, the tire pellet production line is equipped with three crushers (coarse crushing, medium crushing, and fine crushing), magnetic separation, conveying, etc., to turn waste tires into two kinds of products, pellets and wool. This has the advantages of stable performance, low power consumption, and investment in civilians, and the size of the particles can be adjusted at will.

Leave a Comment