Performance and characteristics of circuit board recycling equipment

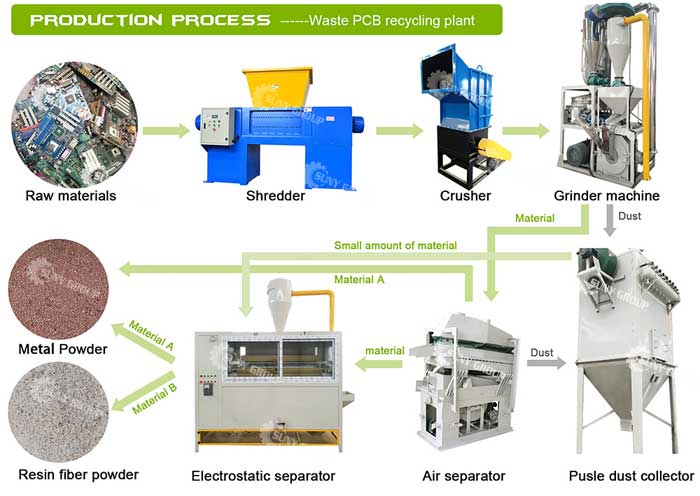

The physical properties of waste circuit boards are special. The circuit board recycling equipment adopts dry crushing and sorting processes for the recycling of waste circuit boards, so that they can be regenerated into recyclable metal powder and resin fiber powder respectively. The production line of waste circuit board recycling equipment describes the performance and characteristics of the equipment:

1. Put the waste circuit boards into the first crusher, and use the roller crusher (first-stage crushing) to roughly crush the waste circuit boards, so that the circuit boards are broken into materials with a size of about 4 cm, and then enter the belt conveyor On the machine, the magnetic separator on the conveyor separates the iron in the material.

2. The remaining materials will be sent to the secondary pulverizer by the conveyor for crushing, making it a powdery mixture of metal and resin fiber powder; the pulverized materials will enter the No. 1 cyclone separator under the action of the negative pressure fan In the process, the external swirling airflow of the cyclone separator settles to the vibrating screen of the air separator, and the light resin powder enters the pulse dust collector connected with the internal swirling airflow of the cyclone separator.

3. Under the action of wind force and vibration, the materials entering the airflow separator separate metal powder materials and resin powder materials to obtain copper, resin powder and semi-finished products. The purity of the obtained copper can reach more than 85%, which can be sold directly.

4. The resin powder obtained will enter the No. 2 cyclone separator under the action of the fan, and the resin powder will settle into the screw conveyor along with the external swirling airflow, and then sent out, bagged and collected by the screw conveyor.

5. The internal swirling airflow will bring light dust into the pulse dust collector. Under the filter of the dust bag, the dust settles to the bottom, and is sent out by the screw conveyor, bagged and collected. The filtered clean air is discharged from the top of the pulse dust collector.

6. The semi-finished products obtained enter the electrostatic sorting machine through the closed screw conveyor, and are sorted again. The semi-finished products obtained by electrostatic sorting are basically materials that are not completely crushed and peeled off. The materials will be conveyed by a screw The machine enters the secondary pulverizer to pulverize again. At the same time, electrostatic separation will obtain higher purity copper and resin products.

Leave a Comment