Circuit Board Recycling Equipment

Circuit board recycling equipment (high voltage electrostatic separation type) is developed by combining advanced technology at home and abroad. The equipment adopts an advanced physical recovery process; the developed crusher and high-voltage electrostatic separation equipment are highly innovative, and its resource-based treatment process route is advanced and reasonable. The equipment can mechanically crush and recycle all kinds of waste circuit boards, computer boards, TV boards, aluminum-plastic boards, copper-attached boards, printed circuit boards and processing waste, waste electrical appliances, etc., with high metal recovery rate and high purity of recovered metals. up to 98%.

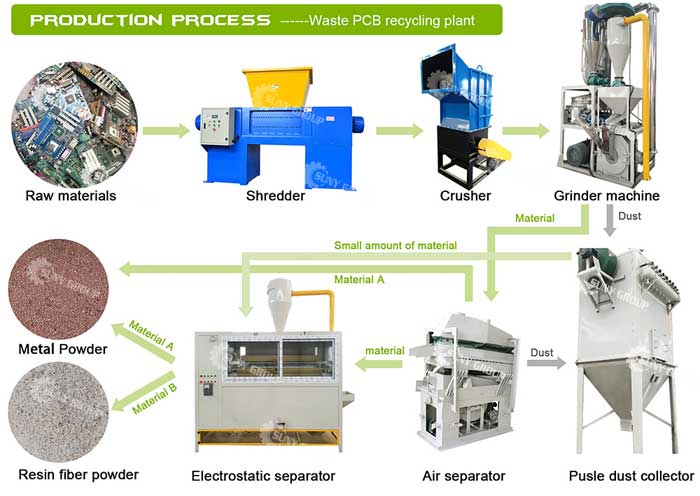

The circuit board recycling equipment (high-voltage electrostatic separation type) consists of a crushing system and a high-voltage electrostatic separation system. The circuit board recycling equipment (high-voltage electrostatic separation type) adopts the process of dry crushing and pulverization, so that the raw materials such as circuit boards become a mixture of metal and resin fiber powder, and then the metal and resin and other non-metals are separated by a high-voltage electrostatic separator. In order to prevent dust pollution during processing, this equipment also adopts a three-in-one dust removal device independently developed by our company. This dust removal device has three levels of dust removal: cyclone dust removal, bag dust removal and air purifier dust removal, which effectively solves dust pollution. problem, all indicators meet the national standard.

1. Advanced new technology of mechanical crushing and high-voltage electrostatic separation is adopted. After crushing and dissociation, the metal and non-metal objects are sorted, and the purity is high; 2. The key technology is to organically combine the special crushing and dissociating equipment for various waste circuit boards, so as to achieve a larger size in the production process. Energy saving effect, and a high metal separation rate is achieved; 3. The unit energy consumption per ton of waste circuit boards is only about 1/2 of the domestic similar products; the hourly processing capacity of the complete set of equipment is up to 1 ton 4. Its sales The price is only 1/5-2/3 of similar equipment at home and abroad, and the copper recovery rate is 3%-5% higher than that of similar manufacturers. 5. The overall performance is good, and it has a unique effect on computer boards, computer boards, TV boards and other circuit control boards, and is also compatible with the recycling of various circuit boards containing capacitors. 6. This production line is an upgraded product of the wind-selection type. Compared with the wind-selection type, the power consumption is reduced, and there is no noise, less manual work, higher automation procedures, higher efficiency, and a smaller footprint. It is a waste electricity (line) circuit. Board recycling to the most ideal production line. 7. Less labor, no pollution, no noise, and flexible equipment placement.

Leave a Comment